Bayer Syringes

An integral part of your total patient care.

Bayer Syringes and Disposables are designed, manufactured and warrantied as part of the total fluid delivery system.

Used with your MEDRAD® Injection System, the syringes and disposables ensure optimal device performance to enhance patient safety.

Made in the USA. Used worldwide.

Bayer syringes are made in our US facilities where we have continuously invested to support and scale our operations in order to meet increasing customer demand, supplying over 300 million syringes in the last five years.

Our commitment to your uninterrupted workflow.

Bayer in Radiology takes extensive measures to ensure the safety and quality of all products. As part of our ongoing commitment to total patient care and uninterrupted workflow, we are dedicated to supporting your organization in delivering safe patient care with every power injected examination.

Our belief in the importance of ensuring product supply and continuity of care for our customers is so strong that in recent months we greatly increased our emergency stock of Stellant syringes and elevated it to the medically necessary product line.

As part of our ongoing commitment to total patient care and uninterrupted workflow, we are dedicated to supporting your organization in delivering safe patient care with every power injected examination.1

There is no substitute for quality.

At Bayer, our syringes are made according to strict quality and reliability controls at every step of the production process. Only Bayer Syringes and disposable products have been specifically designed, manufactured, and validated to work reliably with corresponding Bayer injection systems. As syringes are an integral part of the total injection system, this ensuresyour injector is ready to perform even the most demanding protocols.

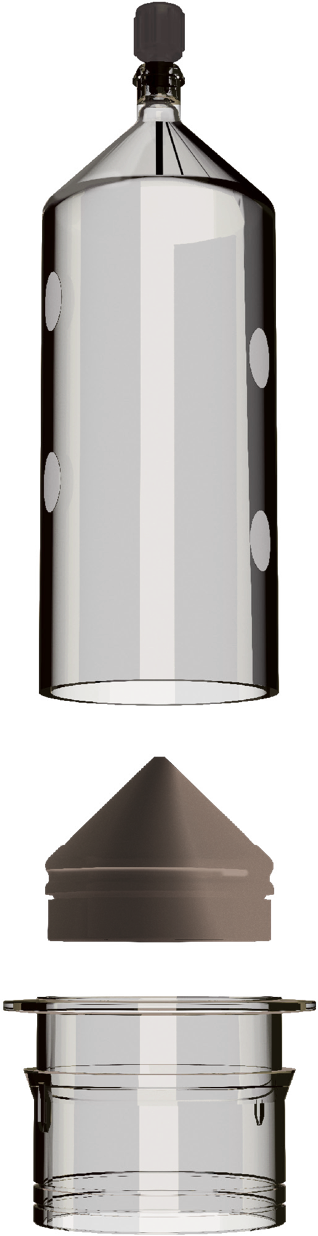

- Designed for your MEDRAD® Injector

Bayer Syringes are designed, tested and warrantied as integral components for your Bayer MEDRAD® Injection Systems.

- Strict Vendor Qualification

Each supplier has been carefully selected, audited and certified to provide materials that completely adhere to our chemical composition and purity specifications.

- Precision Manufacturing

Our US-based manufacturing facility produces syringes to extremely tight tolerances. The volume of silicone coating inside the syringe barrel is precisely controlled. This facilitates optimal device performance and accurate fluid delivery.

- Robust Packaging

Every syringe package adheres to strict specifications and rigorous environmental and transportation simulation testing.

This ensures your syringes arrive at your facility sterile and uncompromised.

Nothing is more important than your patients’ safety. For over 50 years, we have been dedicated to optimizing every aspect of the syringe manufacturing process to assure the highest levels of total fluid delivery performance. Bayer syringes play an integral role in safely delivering imaging fluids to your patients. Every syringe is made from reliable components to help you provide high quality care.

Lab tests performed with non-Bayer syringes found instances where the syringe is technically incompatible with the Bayer MEDRAD® injector.2

Non-compatible syringes may deliver the incorrect dose.

Non-compatible syringes can fail.

Bayer cannot guarantee the performance of your injector with non-Bayer syringes and disposables.3

If a syringe not manufactured by Bayer causes injector malfunction, your Bayer MEDRAD® injector warranty may be invalidated.4

For more information contact your local Bayer representative via our contact page.

References

1 Any drug product used to diagnose, treat, or prevent a serious disease or medical condition for which there is no other drug that is judged by medical staff to be appropriate substitute or there is an inadequate supply of an acceptable alternative.

2 References on file.

3 MEDRAD® Stellant CT Injection System with Certegra® Workstation, Rev. C. Bayer, Indianola, PA, USA, 2018.

4 MEDRAD® Stellant CT Injection System with Certegra® Workstation, Rev. C. Bayer, Indianola, PA, USA, 2018.